From Basics to IIoT Applications

Series Overview

This coming blog series will guide you from fundamental sensor concepts through advanced IIoT applications, providing a complete journey for those new to sensor technology. Note I will only discuss sensors with electrical outputs which can be connected to a data logger or data acquisition unit.

Part 1: Introduction to Sensors

What Are Sensors?

Foundation concepts:

A sensor is a device that detects changes in the environment and converts this into electrical signals that can be measured and processed. Sensors function as the “eyes and ears” of electronic systems, enabling them to perceive and respond to the physical world.

Note that a sensor uses indirect measurement; in other word it uses a physical phenomenon to infer the actual quantity. For example a resistance value can be used to infer temperature.

Key Learning Points:

- Basic definition: Sensors convert physical phenomena into measurable electrical signals

How Sensors Work

The fundamental sensing process:

Sensors operate through a measurement chain that converts physical variables into electrical signals. The process involves:

- Sensing Element: Interacts directly with the environment

- Processing Circuitry: Converts physical variables into electrical signals

- Signal Output: Provides electrical output that can easily be measured or used

Part 2: Sensor Classifications

Analog vs Digital Sensors

Understanding output signal types:

Analog Sensors: Provide continuous voltage, current, resistance, capacitance, inductance etc. output that varies proportionally with the measured quantity. Examples include thermocouples and potentiometers.

Digital Sensors: Output discrete digital values through built-in analog-to-digital converters (ADCs). These sensors provide processed outputs.

In reality all sensors have an analog part that reacts to the physical parameter being measured. Digital sensors just take the output and turn it into a digital signal.

So to truly understand sensors you need to learn about analog electronics/physics. That’s where deep understanding is.

Active vs Passive Sensors

Power requirement classifications:

Active Sensors: Require external power to operate, also known as parametric sensors. Examples include Resistance Temperature Detectors (RTDs). The majority of sensors require some kind of power; all digital sensors require power.

Passive Sensors: Generate their own electrical signals without external power, also called self-generating sensors. Examples include thermocouples and piezoelectric sensors.

Contact vs Non-Contact Sensors

Physical interaction requirements:

Contact Sensors: Require physical contact with the target for measurement.

Non-Contact Sensors: Can measure without physical contact, such as infrared temperature sensors or proximity sensors.

Actually all sensors do need to come into contact with the environment but here we are talking about physically touching.

Part 3: Common Sensor Types and Technologies

Temperature Sensors

Measuring temperature or temperature differsnces:

Thermocouples: Measure temperature through voltage differences between two different metals

Thermistors: Change resistance with temperature variations

RTDs (Resistance Temperature Detector or Device): Use the principle that metal resistance changes with temperature. A common material used is platinum (these types are often called Platinum Resistance Thermometers or PRTs).

Infrared Sensors: Detect thermal radiation for non-contact measurement

Proximity and Position Sensors

Detecting presence and location:

Inductive Sensors: Detect metallic objects using electromagnetic fields

Capacitive Sensors: Detect both metallic and non-metallic objects through capacitance changes

Ultrasonic Sensors: Use sound waves for distance measurement

Photoelectric Sensors: Use light or laser beams for object detection

Pressure Sensors

Measuring pressure and movement:

Piezoelectric Sensors: Convert mechanical stress into electrical charge

Strain Gauge Sensors: Measure deformation to determine pressure

Capacitive Pressure Sensors: Detect pressure through capacitance variations

Vibration or Orientation Sensors

Measuring vibration, acceleration or orientation (including “G”):

Piezoelectric Sensors: Convert mechanical stress into electrical charge

Strain Gauge Sensors: Measure deformation to determine acceleration or angle relative to gravity

Part 4: Sensor Specifications and Selection

Key Specifications to Understand

Critical parameters for sensor selection:

Accuracy: How close the sensor reading is to the true value

Resolution: The smallest change the sensor can detect

Range: The minimum and maximum values the sensor can measure

Response Time: How quickly the sensor responds to changes

Operating Temperature: Temperature range for normal operation

Other Environmental Factors: sunlight, altitude, vibration, shock, electrical noise etc.

Five-Question Selection Framework

Systematic approach to choosing sensors:

- What are you sensing? Identify the physical parameter and target characteristics

- What are the environmental conditions? Temperature, humidity, vibration considerations

- SWaP – Size weight and Power

- What output type do you need? Analog, digital, or switching signals

- Safety Considerations – what happens if the sensor fails?

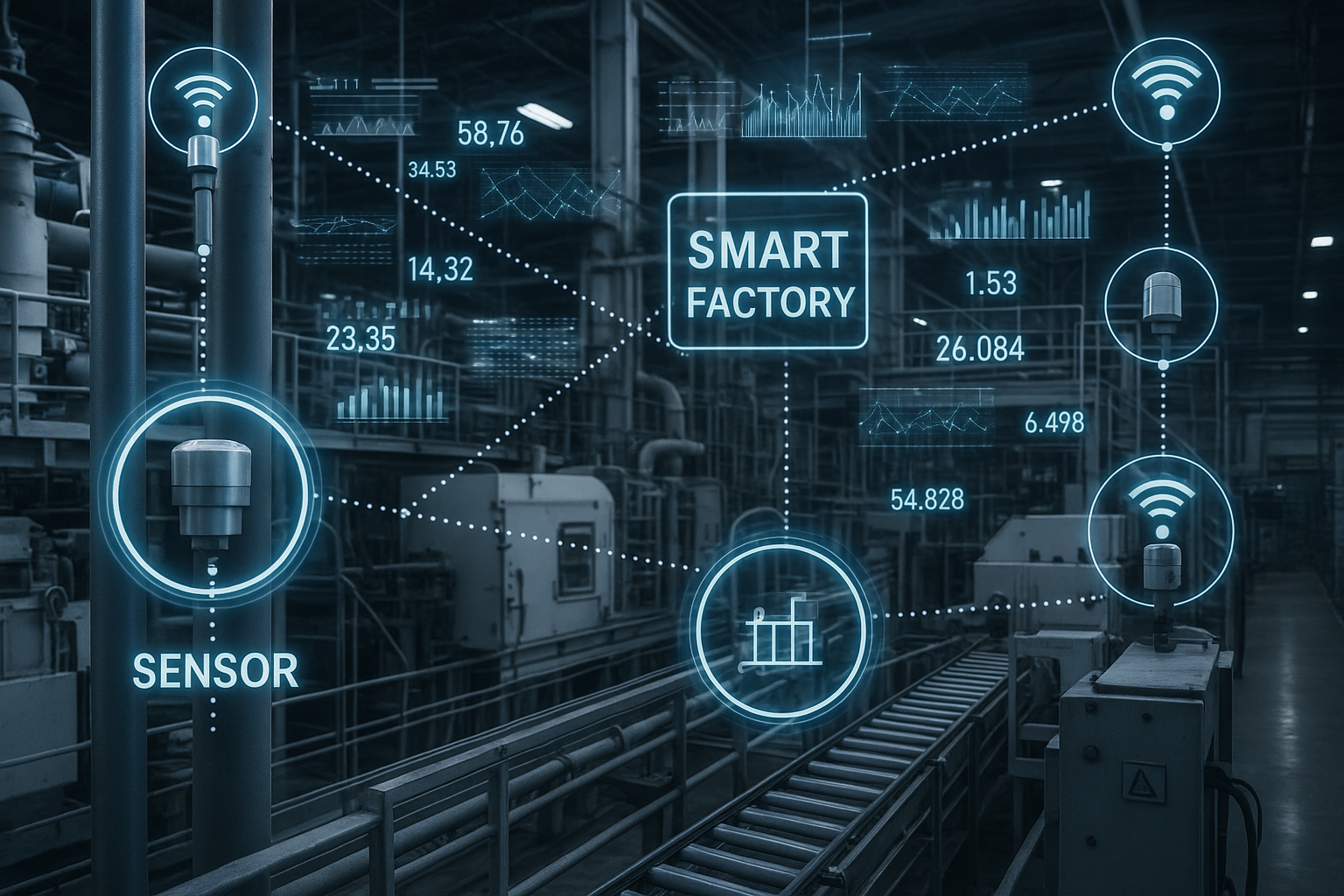

Part 5: Industrial Internet of Things (IIoT) Sensors

What Are IIoT Sensors?

Industrial sensor evolution:

IIoT sensors are industrial sensors, often with integrated sensor and computing functions that connect to larger systems via wired or wireless communication.

Key Characteristics:

- Ruggedised design for harsh industrial environments

- Optional Wireless connectivity for easy deployment

- Optional Integrated or AI processing capabilities

Industrial Applications

Where IIoT sensors make a difference:

Manufacturing: Monitor machine performance, detect anomalies, prevent failures

Energy Management: Track power consumption, optimise efficiency

Safety Systems: Monitor environmental conditions, ensure worker safety

Quality Control: Ensure product standards and process optimisation

Part 6: Sensor Communication and Networking

Communication Protocols

How sensors share data:

Wired Protocols:

- I2C/SPI: For short-distance embedded applications

- Modbus RTU: Industrial standard for equipment communication

- CAN Bus: Automotive and industrial networking

- Ethernet: standard ethernet connectivity

Wireless Protocols:

- Zigbee: Low-power mesh networking

- Bluetooth/BLE: Short-range personal area networks

- Wi-Fi: High-bandwidth local area networks

- LoraWan: Long range low-bandwidth for remote sensing

- Satellite: where all of the above cannot be used

Sensor Networks

Creating connected sensor systems:

Wired Sensor Networks: Use ethernet cables for reliable connections

Wireless Sensor Networks (WSNs): Use wireless technologies for flexible deployment

Network Topologies:

- Star Network: Central hub architecture

- Mesh Network: Distributed, self-healing networks

- Tree Network: Hierarchical data flow

Part 7: Sensor Data and Analytics

Data Collection and Processing

From raw data to actionable insights:

Data Collection: Sensors generate continuous streams of information which can be sent as raw data or else processed and only summary data sent

Data Processing: Filtering, cleaning, and structuring raw sensor data

Data Analysis: Extracting patterns and insights using statistical methods

Edge vs Cloud Processing

Where data processing happens:

Edge Computing: Processing at the sensor or device level for reduced latency

Central Computing: Data is sent to one main computer where it is analysed and processed

Cloud Computing: Cloud based processing for large-scale analytics

Analytics Applications

What can be done with sensor data and how is it turned into actionable information:

Condition Monitoring: Track equipment health and performance

Predictive Maintenance: Predict failures before they occur

Process Optimisation: Improve efficiency and reduce waste

Part 8: Sensor Installation and Mounting

Physical Installation Considerations

Practical deployment aspects:

Mounting Options: Threaded, glued, clamp-on, magnetic mounts

Environmental Protection: protection against dust, water, shock

Cable Management: Proper routing, stress relief

Electrical Connections

Wiring and power considerations:

Power Requirements: Matching sensor needs to available supply

Signal Wiring: Proper shielding and grounding

Connection Types: Threaded, quick-disconnect, terminal blocks

Part 9: Sensor Calibration and Maintenance

Understanding Calibration

Ensuring accurate measurements:

Sensor calibration is the process of measuring the sensor response against known reference standards. Differences can be noted, or used in engineering unit conversion or the sensor can be adjusted. Note that adjustment to “bring the sensor back into spec” has implications; are previous measurements valid?

How Often?

This is always a tricky question as “it depends”.

It depends on the environment and so there is no one correct answer.

A standard period of 1 year is often used but this should be the starting point.

Calibrations should be reviewed to monitor how close the sensor is to going outside of specification (either the supplier’s or user’s specification). If a sensor “fails” calibration then the calibration periodicity is too long. As a sensor ages then the period may need to be reduced.

Calibration Methods

Different approaches to calibration:

In-situ: the sensor is attached to specialist equipment and teh measured parameter is varied

Lab: the sensor is removed and sent to a lab for calibration

Maintenance Best Practices

Keeping sensors operational:

Preventive Maintenance: Regular inspection and cleaning

Predictive Maintenance: Using diagnostics to predict failures, is the signal getting noisy etc.

Corrective Maintenance: Addressing problems as they occur……react to problems

Part 10: Troubleshooting and Problem Solving

Common Sensor Problems

Identifying typical issues:

Signal Issues: No output, intermittent signals, incorrect readings, noise

Power Problems: Voltage issues, grounding problems

Environmental Factors: Temperature effects, contamination, electrical interference