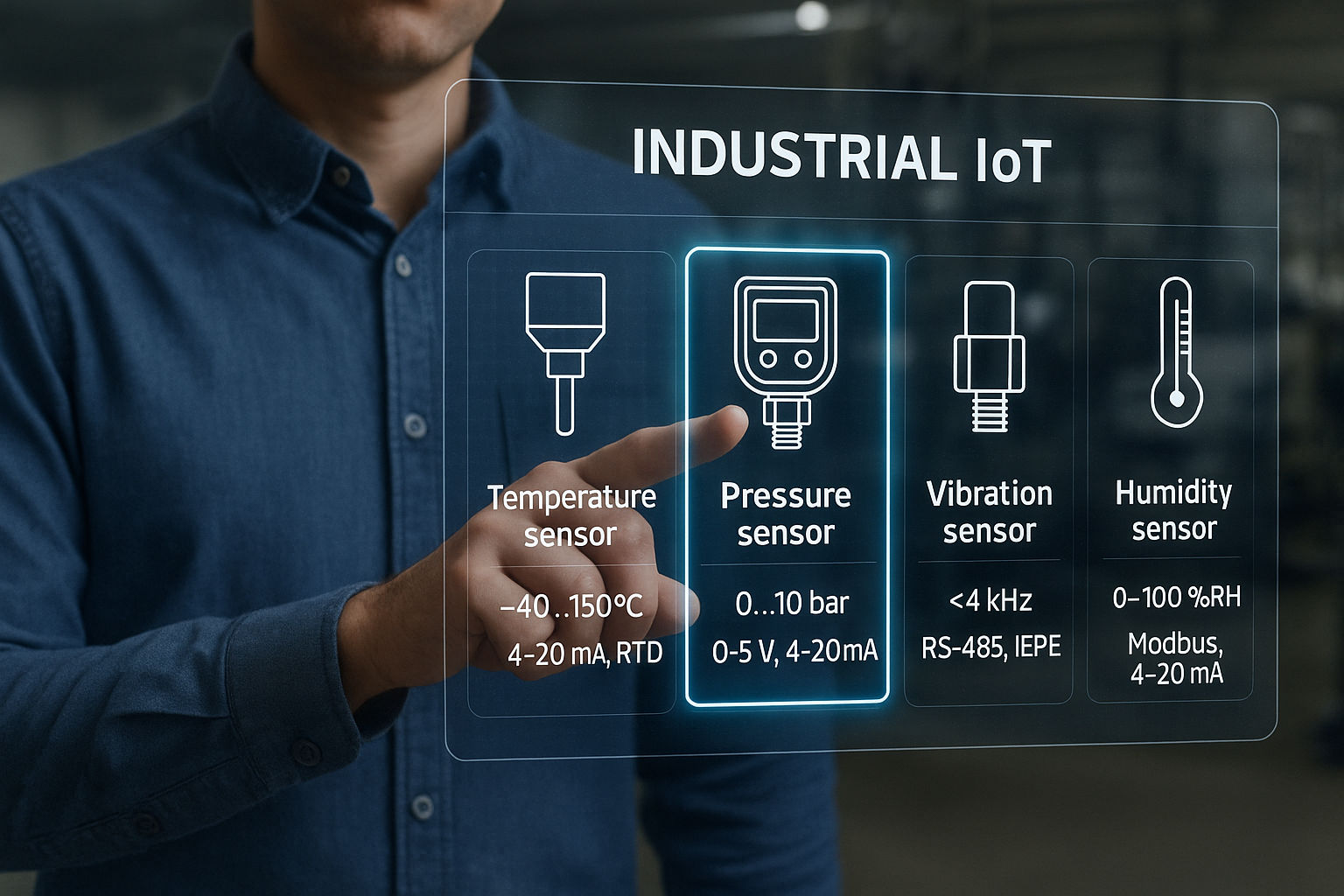

This is a simplification of what things are important when selecting sensors.

There really is much more to it than this but as an introduction here are 5 questions to ask.

1. What defines the parameter that I want to measure?

Examples would be temperature, vibration, flow, pressure, distance etc.

Next ask what the maximum and minimum ranges of the measurement are.

What minimum accuracy do you need; how close is the measurement to the true reading?

What resolution do I need: what is the smallest change that I want to detect?

What is the maximum frequency that I want to measure; how quickly does the reading need to change?

2. What is the environment?

Is there a lot of vibration?

Does the sensor need to operate at high or low temperature?

Is the area very humid or wet?

Is there a lot of dust or salt-spray?

Will the sensor have to withstand harsh chemicals?

Will the sensor get knocked or shocked?

Is there any sensitive equipment nearby that may be affected by electrical noise?

Is there equipment nearby that might emit a lot of electrical noise?

You may already have a list of environmental conditions that the sensor needs to withstand.

3. SWaP – Size weight and Power?

Are there any space constraints?

Are there any weight constraints?

Is mains power available or maybe there’s 24 Volts DC etc?

What current is available for the sensor…….usually sensors do not need a lot of current.

Do you know what level of noise is on the power output (could there be large voltage spikes etc.)?

4. What type of output is required?

If the sensor needs to be connected to an existing data logger then what type of output is needed?

Typical outputs include voltage, 4-20mA, serial, ethernet, wireless.

How far is the sensor from the data logger; this can dictate the type of output needed?

5. Safety Considerations

Are there any safety considerations such as the sensor will be used to shutdown a machine?

Maybe the sensor will be placed in an explosive environment.

What are the impacts if the sensor fails?

As I mentioned, these questions are just a basis for defining the right sensor but for complex environments or safety critical applications then please discuss with your sensor supplier.

Reach out if you need further and more detailed advice.